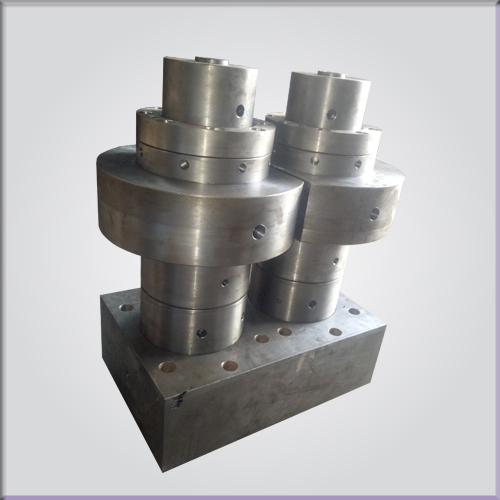

PVC Pipe Dual Die Head

PVC Pipe Dual Die Head Specification

- Diameter

- 63-250 mm

- Features

- High Output, Uniform Wall Thickness, Energy Saving

- Drive Type

- Direct

- Motor Power

- 7.5 HP

- Capacity

- Up to 120 kg/h

- Lubricating System

- Centralized

- Shape

- Cylindrical

- Noise Level

- Low (<70 dB)

- Usage & Applications

- For PVC pipe production extrusion lines

- Surface Finish

- Smooth

- Size

- Custom as per pipe size

- Product Type

- Machine Spare Part

- Material

- Steel

- Technology

- Extrusion

- Power Source

- Electric

- Power

- 7.5 kW

- Voltage

- 380 V

- Pressure

- 16-25 MPa

- Surface Treatment

- Coated

- Dimension (L*W*H)

- 900 x 450 x 400 mm

- Weight

- Approx. 180 kg

- Color

- Gray

- Connection Type

- Flanged

- Suitable Material

- PVC, CPVC

- Application Pipe Range

- UPVC, Plumbing & Casing Pipes

- Cooling System

- Water / Air Cooling Support

- Heating Zone

- Multiple Independent Zones

- Insulation

- Thermal Insulated

- Corrosion Resistance

- High

- Control Panel Interface

- Digital / Analog

- Maintenance

- Easy Maintenance Access

- Die Material

- Alloy Steel + Hard Coating

- Number of Die Heads

- 2 (Dual Head)

PVC Pipe Dual Die Head Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 7 Days

About PVC Pipe Dual Die Head

Versatile PVC Pipe Dual Die Head: Applications and Usage

Widely used by manufacturers, suppliers, and contractors, the PVC Pipe Dual Die Head is essential for UPVC and CPVC pipe production. It finds its application in plumbing, casing pipes, and diverse industrial locations where consistent pipe quality is critical. Ideal for large-scale extrusion lines, this robust machine is favored for both commercial and residential pipe manufacturing, ensuring uniform wall thickness and energy-saving operation across numerous settings.

Flexible Payment and Supply Solutions for Dual Die Head

We offer the PVC Pipe Dual Die Head at a competitive sale price with options tailored to your procurement needs. Dispatching is prompt, and drop-off can be arranged at your specified FOB Port for maximum convenience. With dependable supply ability, we ensure continuous availability to distributors, exporters, and direct buyers, streamlining your purchasing process and maintaining project timelines effectively.

FAQs of PVC Pipe Dual Die Head:

Q: How does the dual die head design improve PVC pipe production?

A: The dual die head enables simultaneous extrusion of two pipes, significantly enhancing productivity and delivering uniform wall thickness, making it ideal for high-output manufacturing.Q: What materials are compatible with this machine?

A: This unit is suitable for processing PVC, CPVC, and UPVC materials, allowing flexible use for a range of plumbing and casing pipe applications.Q: When should maintenance be performed on the die head?

A: Routine maintenance should follow the manufacturers guidelines; however, easy access design allows for simpler, more frequent inspections and upkeep to ensure optimal performance.Q: Where can the PVC Pipe Dual Die Head be used?

A: It is commonly used in pipe manufacturing plants, industrial extrusion lines, and by suppliers catering to construction and water infrastructure sectors.Q: What are the benefits of the advanced cooling and insulation systems?

A: The water/air cooling support and thermal insulation boost energy efficiency, maintain precise temperature control, and extend the dies operational life, resulting in consistent pipe quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extrusion Machinery Spare Parts Category

PVC Pipe extruder Vacuum Chamber

Minimum Order Quantity : 50 Pieces

Surface Treatment : Coated

Material : Steel

Features : Corrosion resistant body, high speed vacuum pump, durable steel construction, easy maintenance

Product Type : Machine Spare Part

Color : Silver

Vacuum Tank Nozzle With Clamp

Minimum Order Quantity : 50 Pieces

Surface Treatment : Coated

Material : Steel & Plastic

Features : Leakproof, corrosion resistant, easy installation, precision engineered

Product Type : Machine Spare Part

Color : Blue

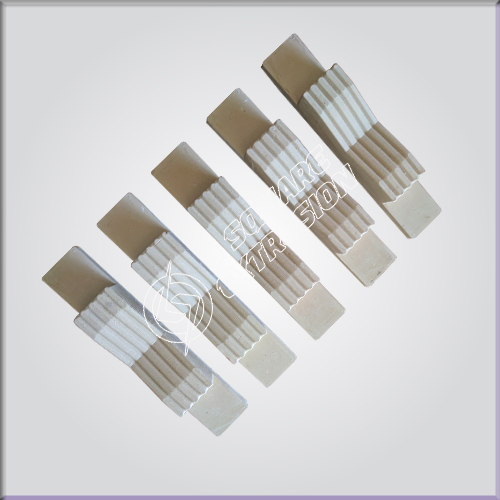

PVC Die Head Bush

Minimum Order Quantity : 50 Pieces

Surface Treatment : Coated

Material : Steel

Features : Corrosion resistant, Durable, High strength

Product Type : Machine Spare Part

Color : Silver

PVC Pipe Haul off Rubber Pad

Minimum Order Quantity : 50 Pieces

Surface Treatment : Other, Textured/Matte for Improved Grip

Material : Rubber

Features : Antislip, Oil Resistant, Durable, Wear Resistant

Product Type : Machine Spare Part

Color : White

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS