PVC Pipe extruder Vacuum Chamber

PVC Pipe extruder Vacuum Chamber Specification

- Noise Level

- Less than 75 dB

- Size

- Customizable or As per requirement

- Shape

- Rectangular Chamber

- Features

- Corrosion resistant body, high speed vacuum pump, durable steel construction, easy maintenance

- Capacity

- Suitable for 16 mm to 315 mm diameter pipes

- Diameter

- Range: 16 mm to 315 mm

- Drive Type

- Direct Drive

- Usage & Applications

- Cooling and calibrating PVC pipes during extrusion

- Lubricating System

- Manual Grease or Oil Lubrication

- Motor Power

- 3 HP

- Surface Finish

- Smooth

- Product Type

- Machine Spare Part

- Material

- Steel

- Technology

- Vacuum Forming

- Power Source

- Electric

- Power

- 7.5 kW

- Voltage

- 380V / 415V

- Pressure

- -0.09 MPa (Vacuum)

- Surface Treatment

- Coated

- Dimension (L*W*H)

- 4000 mm x 450 mm x 1800 mm

- Weight

- 1200 kg

- Color

- Silver

- Control Panel

- PLC based digital control

- Cooling Method

- Spray and water bath

- Mounting Type

- Skid Mounted

- Chamber Accessibility

- Tool-free access design for easy cleaning and maintenance

- Vacuum Pump Type

- Water Ring Vacuum Pump

- Pipe Centering Adjustment

- Precision centering device

- Inlet/Outlet Water Connection

- Stainless steel nozzle with quick-connect coupling

- Pipe Support

- Adjustable support rollers

- Sealing Gasket

- High-grade silicon gasket for leakproof operation

- Window Viewing Panel

- Tempered glass inspection windows

PVC Pipe extruder Vacuum Chamber Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 7 Days

About PVC Pipe extruder Vacuum Chamber

PVC Pipe Extruder Vacuum Chamber: Application Sites & Advantages

This vacuum chamber is expertly designed for use in pipe extrusion plants and industrial PVC pipe manufacturing. Its competitive advantages include precise pipe alignment, corrosion-resistant construction, and low-noise operation. The chamber integrates both spray and water bath cooling for optimal results and durability, making it the preferred solution for fabricators. It is utilised for high-speed cooling and dimensional calibration of pipes, providing efficiency and reliability for various applications.

Certifications, Export Markets & Sample Availability

Certified for top domestic market regulatory standards and constructed with top-tier outlay materials, this vacuum chamber is widely accepted in both local and export markets. Main export destinations include countries in Southeast Asia, the Middle East, and Africa. Samples can be provided upon request, allowing clients to verify the premium quality before committing to bulk orders. The chambers recognised certifications make it a trusted investment for global stakeholders.

FAQs of PVC Pipe extruder Vacuum Chamber:

Q: How does the vacuum chamber contribute to the cooling process during PVC pipe extrusion?

A: The vacuum chamber utilises both spray and water bath cooling methods, ensuring rapid and uniform cooling and calibration of PVC pipes. This maintains dimensional consistency and enhances production throughput.Q: What are the main benefits of the water ring vacuum pump in this system?

A: The water ring vacuum pump delivers powerful suction, maintaining optimal vacuum levels and supporting superior pipe shaping. Its design also ensures quieter operation and long service life.Q: Where is this vacuum chamber typically installed?

A: This chamber is generally deployed in PVC pipe extrusion plants, where reliability, durability, and precise calibration are essential for high-quality pipe production.Q: What certification supports the quality of this vacuum chamber?

A: The vacuum chamber comes with certifications meeting domestic market and international regulatory standards, assuring users of its quality and compliance.Q: Can custom sizes be ordered for special manufacturing needs?

A: Yes, the vacuum chamber can be customized according to specific requirements, accommodating various pipe diameters and plant configurations for enhanced production flexibility.Q: What is the process for cleaning and maintaining the chamber?

A: Tool-free access and tempered glass inspection windows allow for swift cleaning and routine checks, simplifying ongoing maintenance and ensuring uninterrupted operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extrusion Machinery Spare Parts Category

PVC Pipe Die Head Intek Sleeve

Minimum Order Quantity : 50 Pieces

Features : High durability, excellent dimensional stability, easy installation

Product Type : Machine Spare Part

Usage & Applications : PVC Pipe Extrusion Machine

Material : Steel

Color : Silver

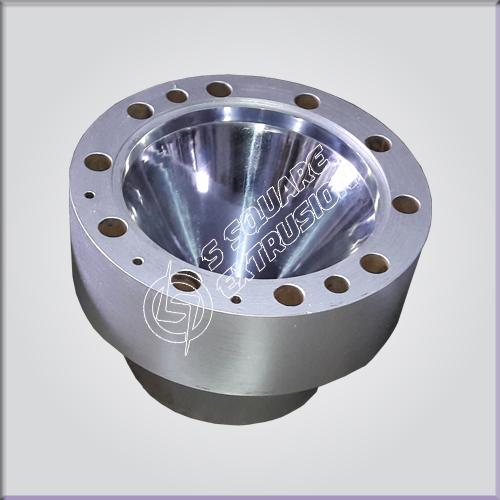

PVC Die Head Bush

Minimum Order Quantity : 50 Pieces

Features : Corrosion resistant, Durable, High strength

Product Type : Machine Spare Part

Usage & Applications : Used in PVC extruder die heads for pipe manufacturing

Material : Steel

Color : Silver

PVC Pipe Haul Off machine Chain Assembly

Minimum Order Quantity : 50 Pieces

Features : Wearresistant, Precise movement, Robust construction

Product Type : Machine Spare Part

Usage & Applications : Used in Haul Off section of PVC pipe extrusion machine

Material : Steel

Color : Black

Vacuum Tank Nozzle With Clamp

Minimum Order Quantity : 50 Pieces

Features : Leakproof, corrosion resistant, easy installation, precision engineered

Product Type : Machine Spare Part

Usage & Applications : Vacuum tanks, industrial filtration systems, fluid transfer systems

Material : Steel & Plastic

Color : Blue

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS